Fully Adjustable Prosthetic

A one-size-fits-all 3D printed leg.

Lance Johnson, University of Wisconsin-Madison

Description

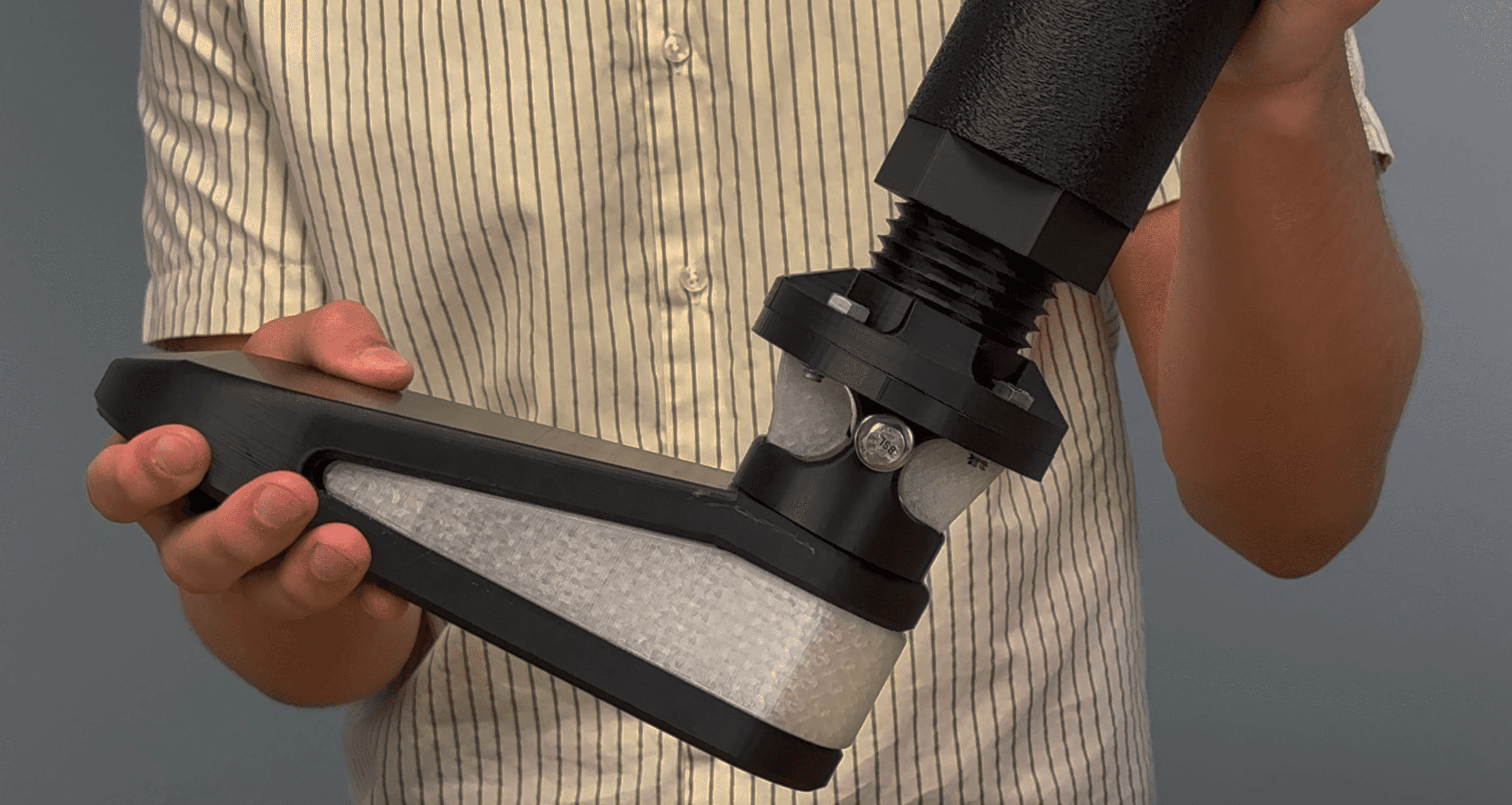

A fully adjustable, 3D-printed, lower limb prosthetic to improve long-term outcomes particularly for children and adolescents living with lower limb loss.

Introduction

As of 2017, nearly 58 million people globally were living with a limb amputation, a number expected to rise annually. The primary causes of amputations vary by region, with peripheral vascular disease, diabetes mellitus, and trauma being the leading causes. Over 50% of these amputations are transtibial, or below-the-knee. Prosthetic limbs have been a key treatment for amputees, with technological advancements significantly improving patient outcomes. However, prosthetics remain costly, with basic lower limb prosthetics ranging from $5000 to $10,000, and adaptation to these devices is challenging, leading to a 22% abandonment rate within the first year. Users face numerous issues, including phantom limb pain, muscle imbalances, discomfort, and social stigma.

Problem Statement

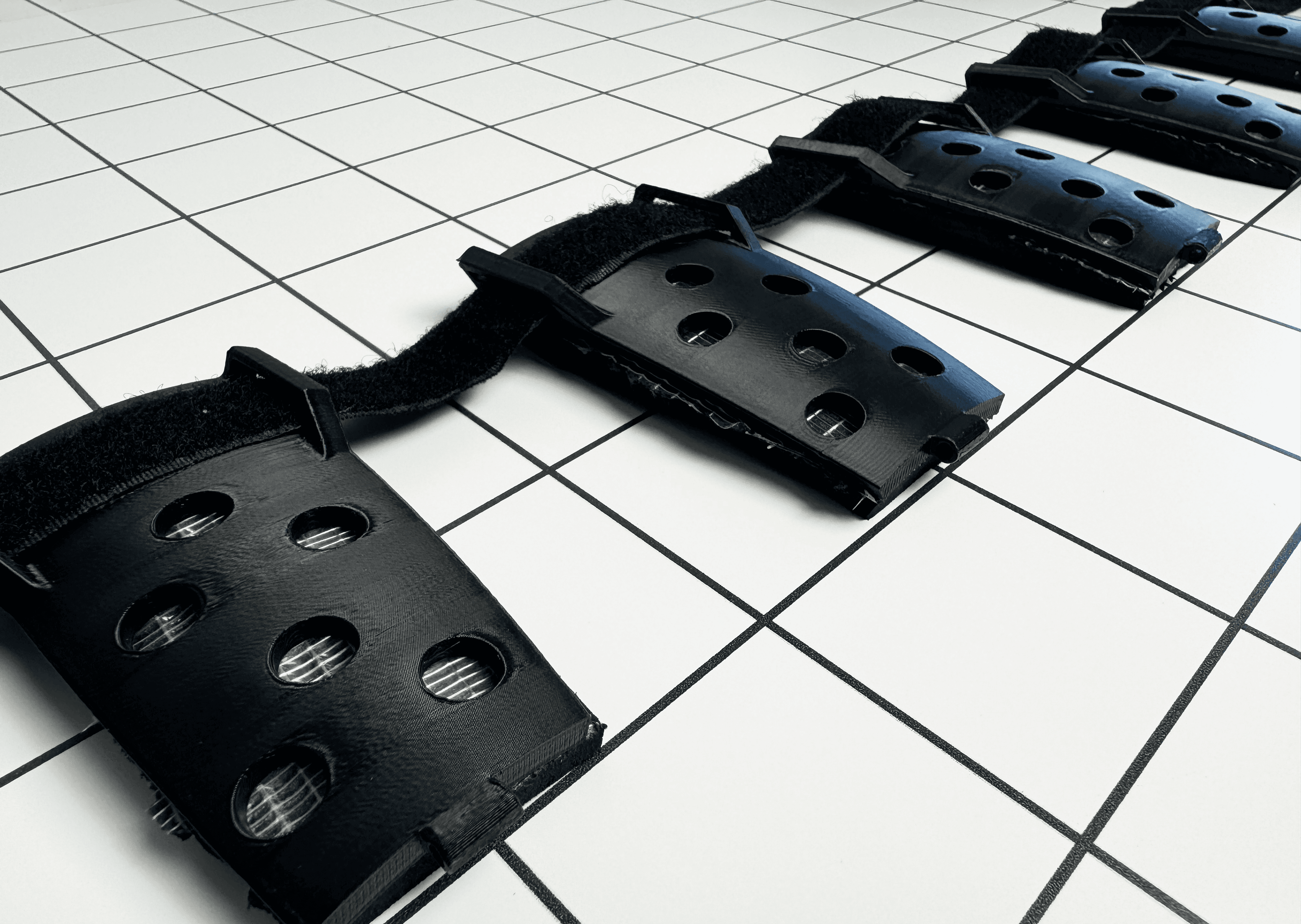

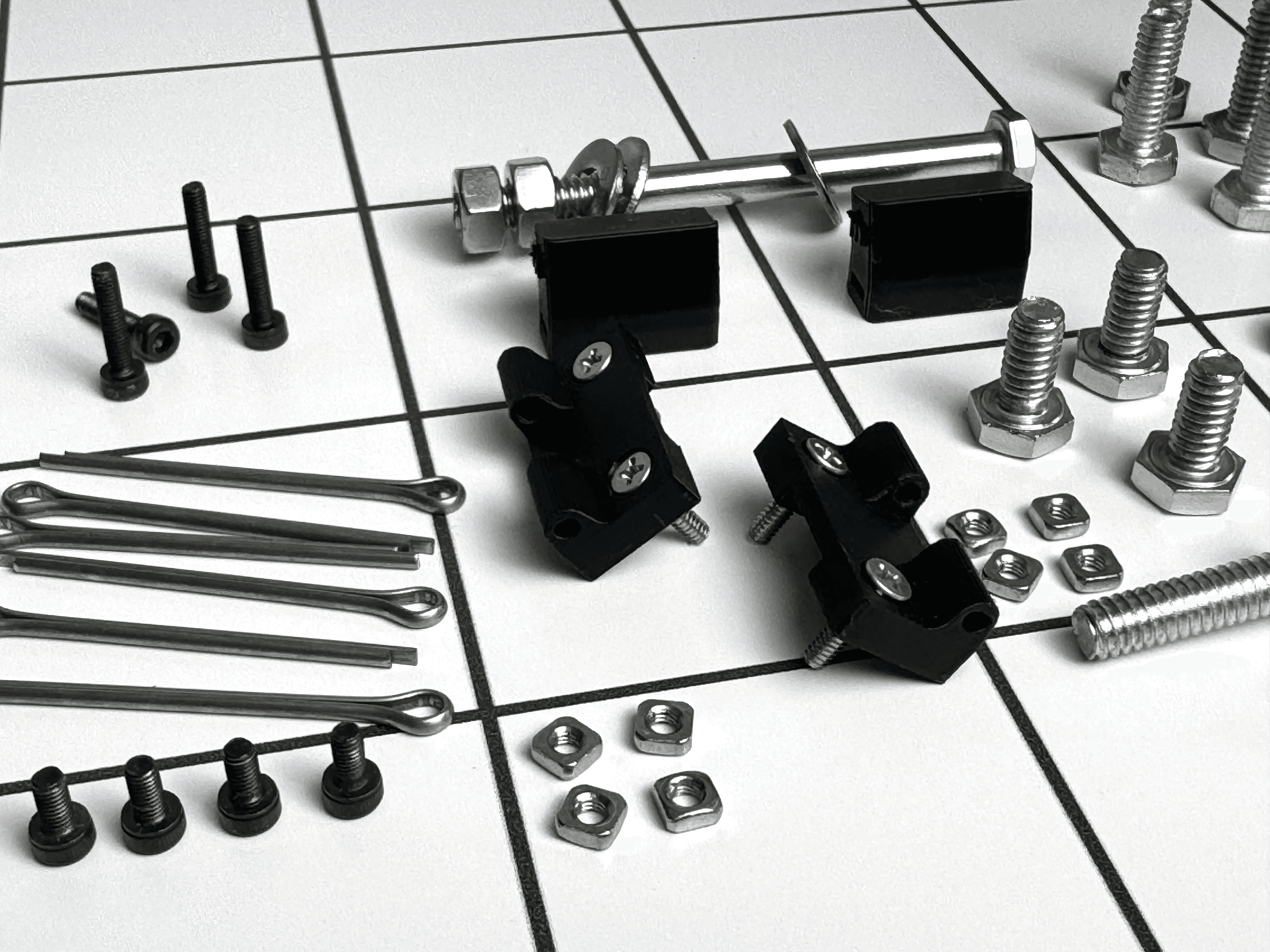

Conventional transtibial prosthetics include a socket, suspension method, pylon, and terminal device/foot, usually customized through 3D scanning technology. This method, while effective, is time-consuming, expensive, and inaccessible for many amputees. Additionally, the fixed size of these prosthetics poses problems for growing children and adolescents, necessitating frequent replacements.

Project Goal

This project aims to create a low-cost, adjustable transtibial prosthetic that can be 3D-printed and customized to fit a wide range of users. This prosthetic is designed to grow with the user, particularly benefiting children and adolescents.

Team Members

Lance Johnson - Project Originator and Concept Designer

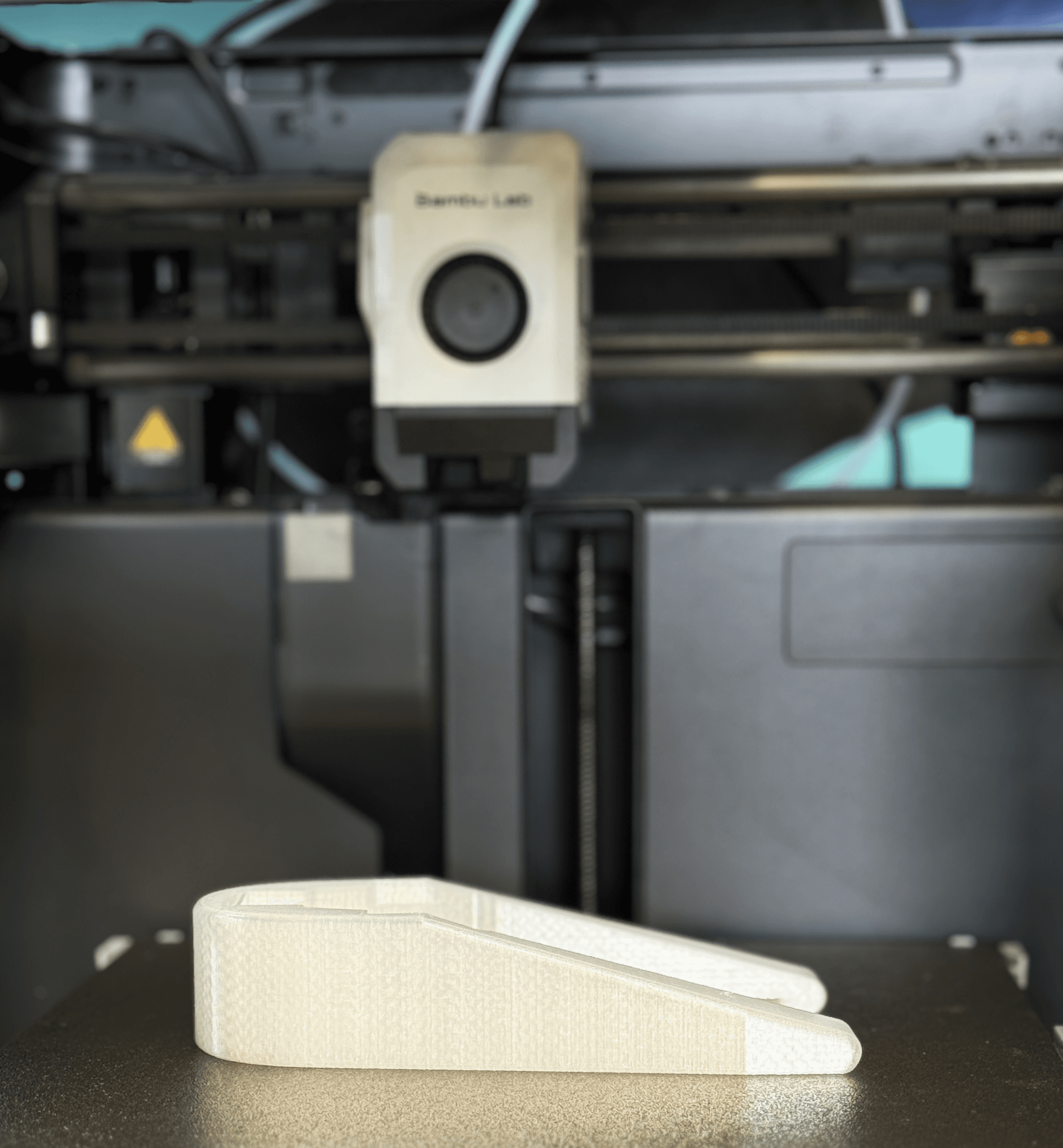

Ron Durham - Liaison, 3D Printing Specialist, and Project Coordinator

Ethan Shute - Lead CAD Designer and Prototyping Specialist

Documentation

View the full documentation on Thingiverse right here.